Staybull African Mahogany

Staybull Flooring™ products are processed from solid kiln-dried lumber and rips. These flooring materials should be acclimated and installed in accordance with the National Wood Flooring Association recommendations. As each installation is unique, we urge you to

contact us and a professional flooring installer for recommendations concerning jobsite evaluation and installation. Please contact your Staybull Flooring™ representative with any questions and view our website for general tips and guidelines on installation.

contact us and a professional flooring installer for recommendations concerning jobsite evaluation and installation. Please contact your Staybull Flooring™ representative with any questions and view our website for general tips and guidelines on installation.

Common Name : |

African Mahogany |

Botanical Name : |

Khaya Ivorensis |

Raw Material Source: |

Africa |

Product Description: |

Edge glued plank flooring |

Grade: |

Staybull Flooring™ Select and Better |

Knots: |

Closed pin knots allowed. |

Checks/Cracks: |

Selected for minimal surface checking in up to 5% of pieces allowable. |

Grain Pattern: |

Grain is straight to interlocked. |

Percentage Sapwood: |

Selected for minimal sap, up to 10% allowable. |

Color: |

African Mahogany heartwood ranges from light to deep reddish-brown in color. |

Weight: |

2.2 lb/Sq. Ft. Approx. |

Standard Dimensions: |

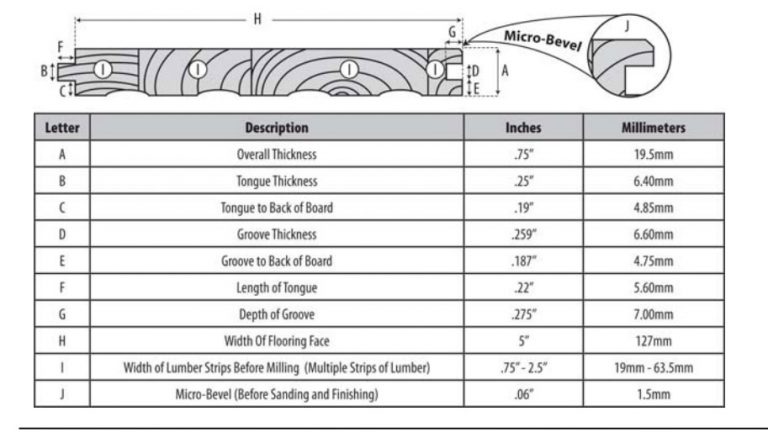

Thickness: 3/4” (19mm) Width: 5” Face (127mm) Length: 1’ – 7’ (.304 – 2.13 meters), Average lengths are 3.5’ (1.06 meters) or longer. |

Edges: |

Tongue and Groove with micro bevel. |

Ends: |

End matched tongue & groove – no micro bevel. |

Textures Available: |

Smooth |

More Info |

|

Installation: |

Staybull Flooring™ can be installed on and above grade level. It is not recommended that this flooring be installed below grade. Installation procedures may vary, see installation instructions, maybe installed over plywood subfloor or glued to a well aged concrete slab (12 months or older). |

Moisture Content: |

Shipped at 6%-8.5% average. Moisture content may vary some based on the humidity level of the installation site. Therefore, we recommend flooring be acclimated on the job site in the same environment in which it will remain once installed, for a period of 1 to 3 weeks. |

Finishes: |

Pre-finished with Ceramic UV Cured Finish. |

Stability: |

Will expand and contract slightly less than Red Oak. |

Waste: |

We recommend 5% – 10% cut and waste on traditional sub floor installations. |

Janka Rating: |

830 |

Advantage Flooring products are processed from solid kiln-dried lumber and rips. These flooring materials should be acclimated and installed in accordance with the National Wood Flooring Association recommendations. As each installation is unique, we urge you to contact us and a professional flooring installer for recommendations concerning jobsite evaluation and installation. Please contact your Advantage Flooring representative with any questions and view our website for general tips and guidelines on installation.

More Product Information